An old friend came by last week looking to replace a few parts on his old Sears Custom 10 Sierra lawn tractor. The tractor was manufactured back in the 1970’s and parts are impossible to find these days, including the mower blades. He purchased a set of blades that were the same length as the original blades, but was unable to find a set with the correct center hole. His blades used a “dog drive” hub to connect the blade to the output shaft of the mower deck gear boxes.

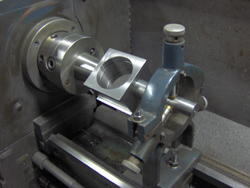

One face of the dog drive has a male drive key (front-right) and the other face has a female socket drive (front-left). The old, worn out sample piece can be seen between the two new pieces. The original blade can be seen behind the new blade.

I used a drop from 2.50″ diameter 4140 bar stock to make the dog drives. I turned and faced the material and then drilled a 10 MM diameter pilot hole through the center and then mounted it to a fixture plate. I machined the slot using on my Bridgeport Series One CNC mill and a 0.375″ diameter carbide end mill .